Quality management definition

Imagine that you operate a lemonade stand out on your neighborhood street corner. Business is going well, but you’ve started to recognize a few things that could make your stall run smoother. You’ve identified, for instance, that a different store offers fresher lemons. And maybe your juicer is on its last legs, too? Perhaps you should invest in a new one to improve the taste and time to serve?

You plan to make these changes, track how things change over time, and then see if there are even more improvements that can be made later down the line.

At its absolute simplest, that’s what quality management is.

Often shortened to QM, quality management is the process of evaluating quality across the whole of an organization, so that you can make timely improvements.

In a business environment, quality management is what happens when you bring quality assurance (QA) and process improvement together. But what that really means in practice is that you’re looking to formalize that improvement.

The process involves setting goals, identifying where these goals aren’t being met, and adjusting where relevant to get things back on track.

In other words? Quality management is how you find areas where things could be running more smoothly, and how you’ll take action to close experience gaps.

Free eBook: Making the business case for contact center transformation

Understanding quality management systems in business

Customers’ expectations are higher than ever, so companies that successfully meet these rising expectations have a tremendous opportunity to differentiate themselves. These heightened customer expectations and increasing standards mean that quality assurance and quality management are incredibly important.

In business that means keeping a keen eye on every process and touchpoint to find out where things could be made better – and how. Two example areas where quality management is most applicable are manufacturing/shipping and customer support.

Because quality management is the combination of quality assurance (QA) and process improvement, it’s a critical component of successful contact center operations, as one key example.

Potentially a customer’s first point of contact, the contact center presents a unique opportunity for an organization to directly and often permanently impact a customer’s experience and overall perception of the company.

If a representative fails to disclose a privacy statement, or is rude to a customer, for instance, that could inadvertently land the organization in legal trouble, elicit bad press, or both.

Quality control and quality management systems can improve that contact center performance by clearly defining desired representative behaviors, identifying interactions that miss the mark, and providing mentorship based on these “coachable moments.”

So, a mature quality management program not only improves customer perceptions of an organization but also empowers representatives to become and remain effective frontline drivers of both positive CX and consistent regulatory compliance.

Quality improvement methods: What are the stages?

Total quality management is essentially your strategic approach to ensuring quality.

This includes planning as well as evaluation, helping to change QA scores from negative to positive through targeted action. While quality assurance methods are vital for a business to provide services that are productive and memorable, quality management takes things one step further.

It helps you not only to flag potential quality issues but to take action to ensure that other issues across your business are resolved.

While there is a spectrum of maturity, most quality improvement methods follow these core steps:

1. Establish Expectations

Rubrics or scorecards often evaluate performance by examining desired behaviors and outcomes. Some of these may be easier to consistently measure than others, but the goal here is to figure out what the ideal scenario is.

2. Evaluate

In the example of a contact center, we’d then evaluate a percentage of representatives’ customer interactions. Auditors look to compare adherence to our expected behaviors.

3. Coach and adjust

If we find discrepancies or areas for improvement in our example contact center, we’d then look to coach and adjust representatives’ performance to reinforce our organizational standards and expectations.

4. Analyze Trends

QM programs build on QA processes by uncovering trends – these trends are then turned into operation-wide improvements. At the end of the process, you’ll analyze your results, and begin the process over again to keep things continuous and cyclical.

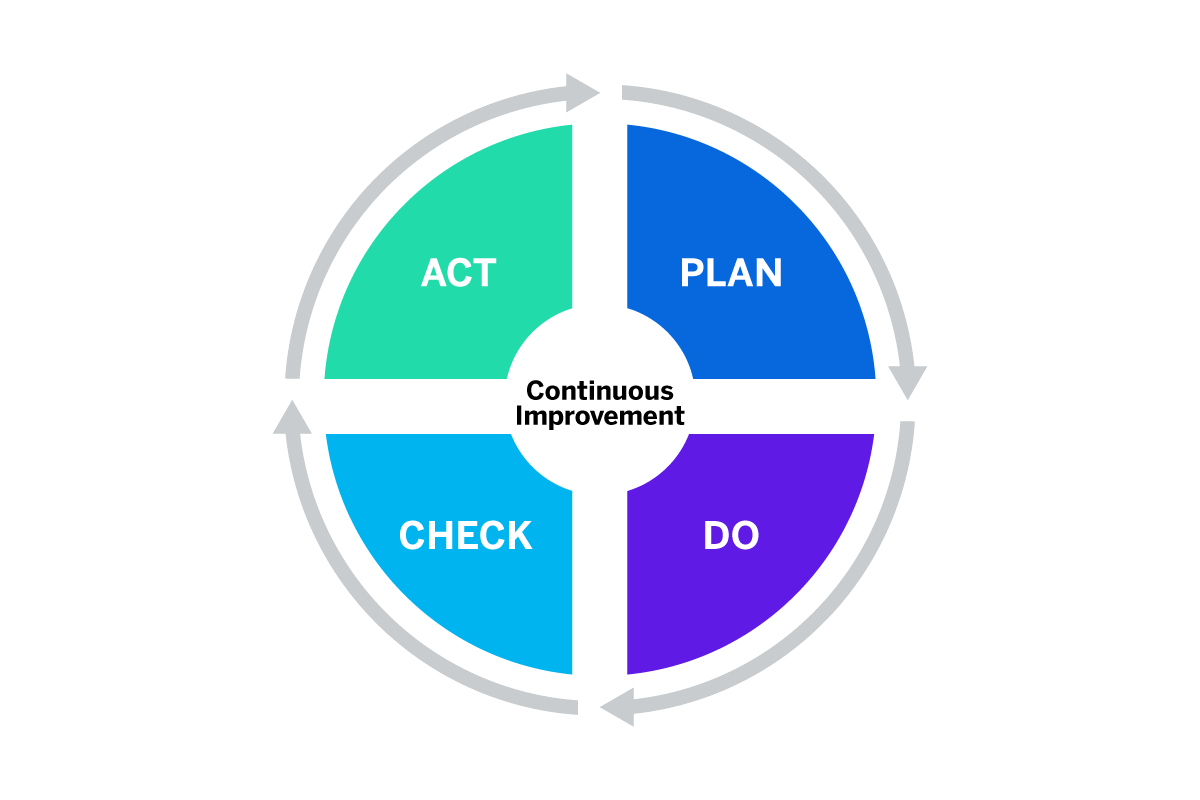

Another way of looking at quality management principles is through the ‘PDCA’ model, in which a testing environment encompasses the following steps:

Plan – The planning phase is where the initial quality standards are drawn up and decided upon. Whether you’re following a standardized framework or not, this is where your quality engineer will decide what ‘quality’ means for your product, service, or team.

Do – The ‘do’ phase is simply where you carry out the processes and procedures that you’ve defined in the planning phase.

Check – In this phase, we collect data to see how well things are performing based on the criteria we’ve designed. You’ll compare actual outcomes with your expected ones, and see how that marries up to your overall quality objectives.

Adjust – Also known as the ‘Act’ part of an overall quality test strategy, this is where you’ll make the changes that your findings point to, to improve whatever it is that your QA testing was tracking. As we’ve mentioned, the quality improvement process is an ongoing one, so it makes sense that the process for quality management – whether it’s for customer support or in software testing – is cyclical.

With that in mind, it’s best to think of the ‘Adjust’ phase as leading back into the ‘Plan’ phase.

What is a quality management system (QMS)?

The above section describes the overall process flow for quality management, but how do you actually put that process into practice? How do you ensure total quality management?

A quality management system (QMS) is the answer here – a formalized process and toolset that documents each step, the desired outcomes, the ways to improve, and the results.

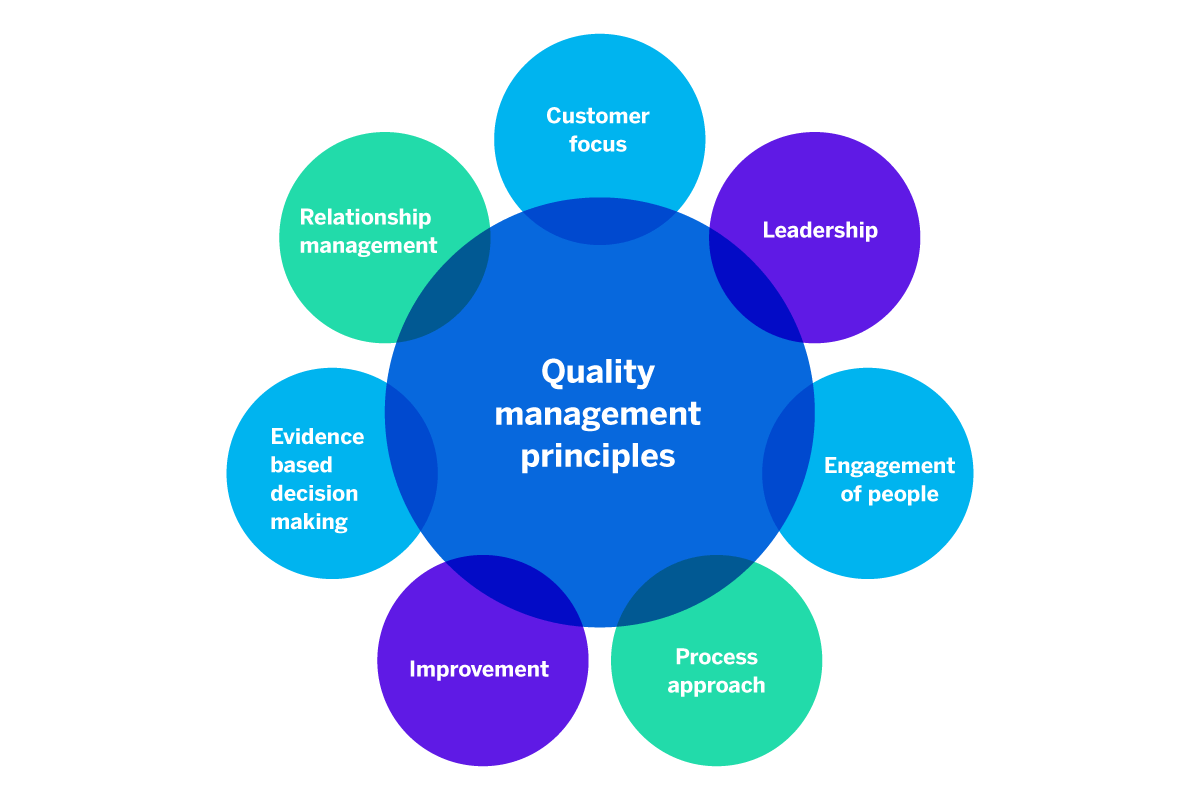

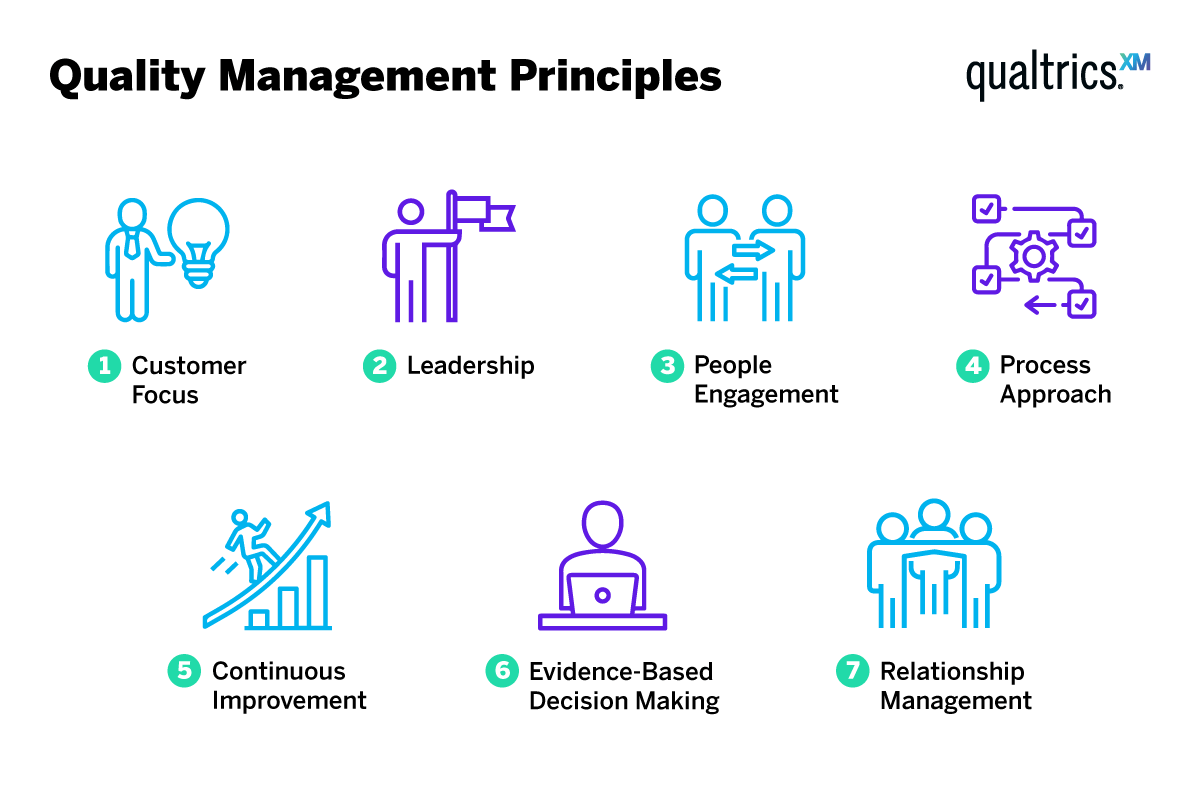

Some quality management systems are bespoke to individual organizations, others offer a quality management system standard for cross-industry certification. For example, the ISO 9000 and ISO 9001 are internationally-recognized frameworks for quality management, describing seven quality management system principles:

- Customer focus

- Leadership

- Engagement of people

- Process approach

- Improvement

- Evidence-based decision making

- Relationship management

Likewise, the CMMI (Capability Maturity Model Integrated) framework works on the principle that organizations willing to put time and resources into process improvement are more mature and capable than others. It describes maturity and capability across several stages, from ‘Incomplete’ to ‘Defined’.

Whichever quality management system (QMS) you choose to apply, you’ll want to employ the use of intelligent, enterprise quality management software that can handle some of the heavy lifting – and scour large datasets – for you. We’ll cover those shortly, but first…

Why are quality management systems important?

Implementing a thorough and standardized quality management system is the only real way to guarantee measurable improvement to your business systems on an ongoing basis. Through documentation and planning, a quality management system aids with compliance, organizational buy-in for change, transparency, and – ultimately – builds customer satisfaction.

Quality management systems, aided by the right technology to implement them, also ensure that opportunities don’t slip through the cracks – and the more robust the system, the more you can track.

For example, when evaluating call center performance on an ad hoc basis, soft skills requirements can seem fuzzy and leave much up to the subjective interpretation of your auditors. Manual quality management processes can also introduce the potential for subjectivity and human error.

These one-off endeavors are also limited by the number of audited calls, hours in a day, and the audit timeframe. And without a system in place, coaches may not give feedback to agents until much later, making any interaction harder to learn from. A lack of historical records and documentation, meanwhile makes it challenging for agents and supervisors to track improvement over time.

In fact, there are three clear benefits to implementing a quality management system within your business:

Consistency

By documenting, testing, and improving your organizational processes, you’re effectively stamping out inconsistencies. An ever-improving business will naturally be an ever-more consistent one, and that consistency is often synonymous with cost-saving efficiency.

Evidence-based change

With total quality management, you can take the guesswork out of prioritizing what needs to change and what’s working well. A statistical quality control methodology leads to decision-making steeped in empirical evidence.

Increased profit

There are several documented reasons why quality management systems can lead to increased profits, most notable among which are improved efficiency and an improved reputation within your marketplace.

Beyond all this, however, is the fact that for both business partners and customers/clients, not having a robust quality management system in place is now seen as bad practice – with many businesses requiring their partners to have a recognized certification.

After all, if you don’t have a quality management system in place, it sends a message that you’re not seriously invested in improving the quality of your processes, products, or services.

Free eBook: Making the business case for contact center transformation

How to choose a quality management system

When we talk about choosing a quality management system, in practice we’re talking about choosing a business intelligence software suite. That’s first because a QMS is more than just a series of guidelines, and secondly because the kind of data capture that modern businesses should want to undertake is often too large (and too always-on) to be done manually.

Extreme sampling can make it harder to find significant trends that inform smart coaching, but if an organization only considers a small sample of interactions, the insights it finds may be misleading or inaccurate. So a software-based QMS, powered by AI and with real-time data capture, is the best way for most organizations to implement quality planning and management.

Here are four factors that should go into your decision when choosing your quality control tool:

Industry relevance

Not every kind of QMS applies to every industry, so be wary of relevance for your industry. For example, while ISO 9001 certification can be applied to any industry, the automotive industry has IATF16949 certification, and Food is measured against the ISO 22000 standard. Moreover, does the company whose software solution you’re looking at have experience in, and understanding of, your industry?

Performance and Scalability

Any decent quality improvement software should be able to scale with your business and be able to monitor any process in your business – no matter how big or small. Being able to run in real-time and with large datasets is a plus, as is being able to visualize data in an understandable way.

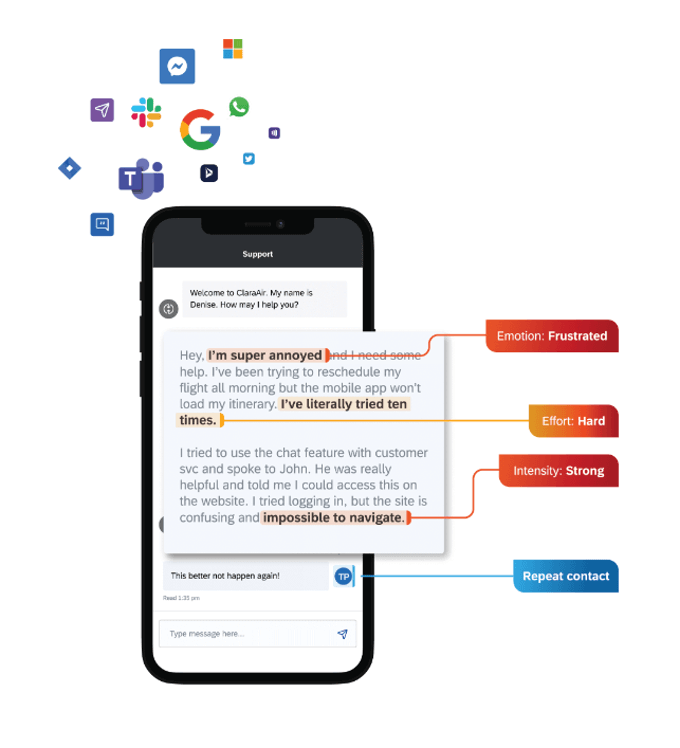

Intelligence

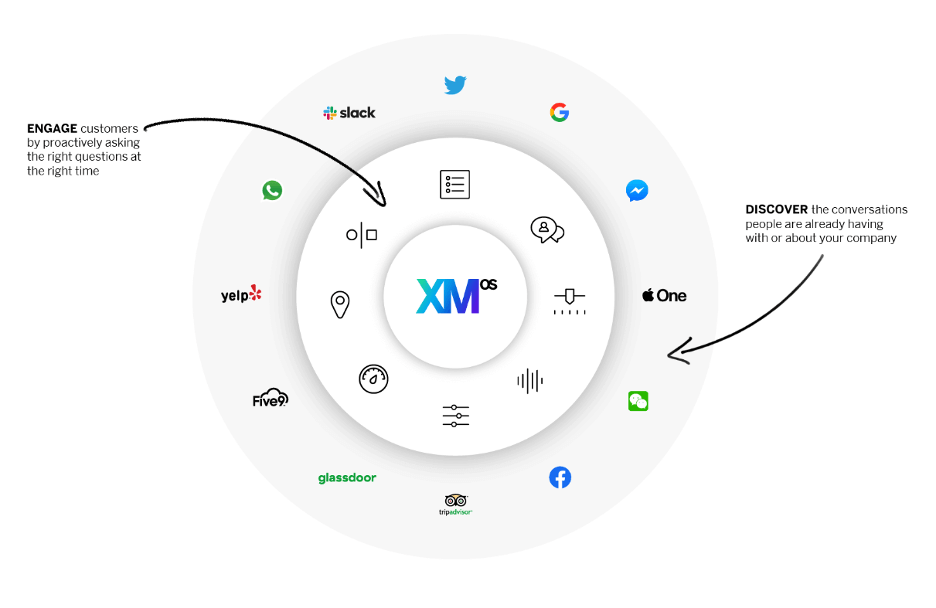

AI and machine learning can help modern quality management systems complete tasks at a scale that humans can’t, but they can also offer quality management across traditionally qualitative vertices. In a call center, for instance, you’ll want your chosen software package to be able to automatically understand sentiment, points of friction, and emotion – not just the number of resolutions.

Suggestions and actionability

Finally, you’ll want your software-based quality management suite to be able to suggest actions that can really make an impact on quality. That means providing a holistic view of the overall operation, alongside one that’s granular enough to make practical, actionable suggestions that boost customer satisfaction.

Quality management systems in practice: 7 steps to success

Want to better understand what quality management looks like in practice? Let’s take the ISO 9000 and ISO 9001 QM frameworks – one of the best-known quality management systems – and look at how its seven QM principles translate to tangible business improvements…

1. Customer focus

Not much in business matters more than your customers. Customer focus, then, means auditing every touchpoint of the customer experience and improving things wherever possible, to better meet customer expectations. That might mean using technology that can help streamline or improve agent performance in the contact center.

Or it might mean learning where they’re running into issues using your website and working to close those experience gaps. Either way, the aim is to boost customer satisfaction no matter how they’re interacting with your business.

2. Leadership

There’s a reason this comes before employee engagement in the list; great operational efficiency and enthusiasm should come from the top down. In practice, that usually means being able to set and monitor clear goals and objectives for staff.

Leadership in any organization can be a tricky proposition, but the more egalitarian and transparent the playing field, the better.

3. Engagement of people

Employees like to be involved in processes and given the ability to define their own objectives. But moreover, employees will always feel more engaged if they’re given the right tools to do the job.

In the contact center, for example, that might mean deploying contact center experience management software that can use natural language processing and AI to assist agents in real-time, providing customer context, empathetic prompts, and help with script compliance.

4. Process approach

Formalizing and streamlining business processes. No organization should be flying by the seat of its pants – instead, it’s important to try and capture a best-in-class version of everything that routinely happens, and work toward besting it.

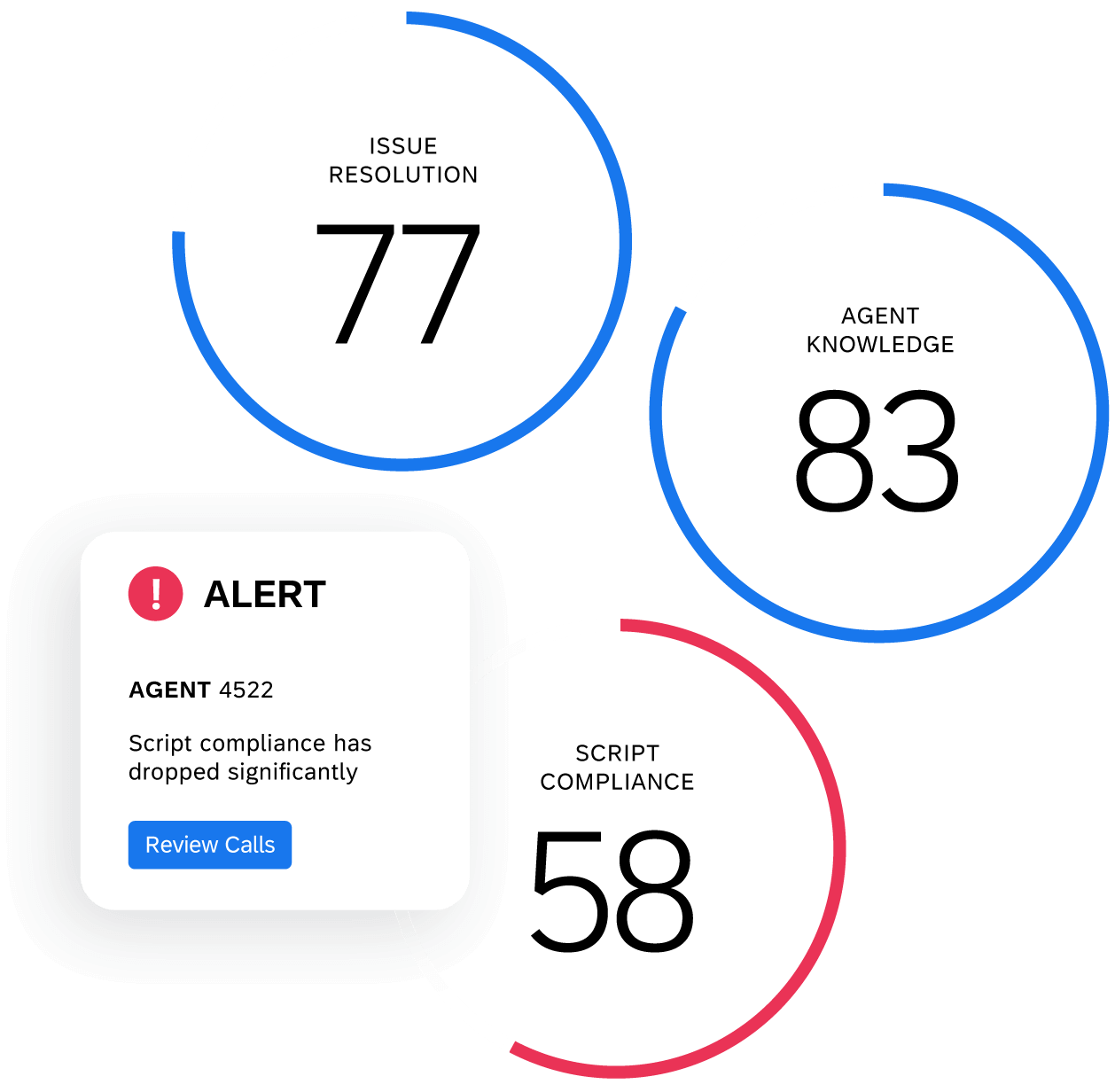

Using the contact center as an example again, that could be through using technology that can auto-score agent performance in real-time, rather than using a manual process that misses interactions and nuance.

5. Continuous improvement

Improving the various parts of your business’s operations isn’t a one-and-done task. It should instead involve constant and continual evaluation and a routine of taking action based upon new learnings.

Say you’ve taken steps to enhance a supplier relationship, for instance. You’ll want to check in on that relationship at scheduled points to ensure that things are still firing on all cylinders. If not, then you’ll need to look at how things can be tweaked.

6. Evidence-based decision making

A key part of standardizing your quest for improvement is that you’ll generate data and insight that fuels decision-making.

Part of that is onboarding the right tools for the job, whether it’s social listening capabilities, or contact center agent scoring. Whatever the case, the goal is to generate data from these organizational processes that can be compared to previous periods, and that can be used to suggest your next steps on the road to improvement.

7. Relationship management

Any relationship your business needs to function, whether it’s suppliers, dealers, retailers, or any other third party, needs to be monitored, managed, and meaningfully enhanced as time wears on.

That might mean swapping suppliers when you realize there are more reliable options available, or it might mean moving to work with new partners who can help you meet your sustainability goals. Once these relationships are locked in, there should be a set of quality improvement-focused organizational processes in place to ensure that things only ever get better – and demonstrably so.

Quality, controlled: The Qualtrics approach to quality management

Qualtrics’ quality management solution is specifically designed for contact center professionals and harnesses the power of our entire product suite.

With its industry-leading conversation analytics, you’ll be able to move from manual sampling to automatically evaluating 100% of contact center interactions, leveraging powerful rubrics and targeted coaching opportunities that cater to every member of your organization.

Eight Fortune 100 companies are already using our intelligent quality management solution to explore insights, uncover potential call deflection and self-service opportunities, automate QA/QM, enable efficient agent coaching processes, measure drivers of customer satisfaction, and improve customer experience across all channels.

With that powerful feature set, Qualtrics is driving higher loyalty, frictionless customer journeys, and reduced churn more easily and accurately – increasing QM efficiency by 30% on average as a result.

With Qualtrics, every member of the contact center – from supervisors to representatives to speech analysts – is involved in a humanistic cycle of improvement.

Free eBook: Making the business case for contact center transformation